Warning

This guide is intended for experienced operators only. It is advisable to review your printer's operating manual and understand the capabilities of its printheads before proceeding.

The latest versions of Caldera Direct-to-X RIP feature an optional manager that allows you to adjust the density and size of ink drops globally and customize the values for each ink, based on your production needs.

Context

Understanding droplet sizes and density is useful for achieving high-quality prints in digital inkjet printing. These factors influence not only the visual outcome but also the efficiency and cost-effectiveness of the printing process.

By carefully managing these parameters, printers can produce vibrant, detailed, and consistent prints that meet the demands of various applications.

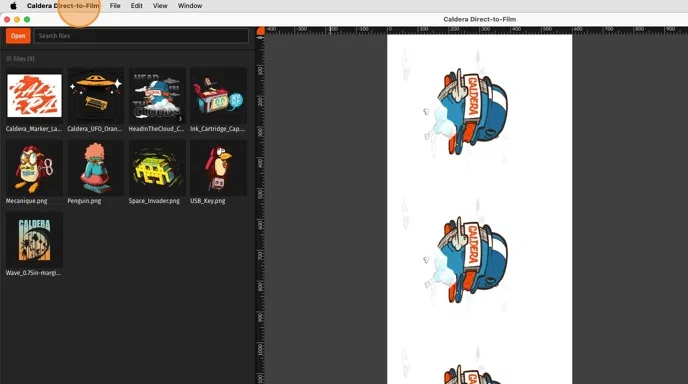

Access the Custom droplet manager

- Depending on your operating system, click on Caldera Direct-to-X or Edit and go to Settings…

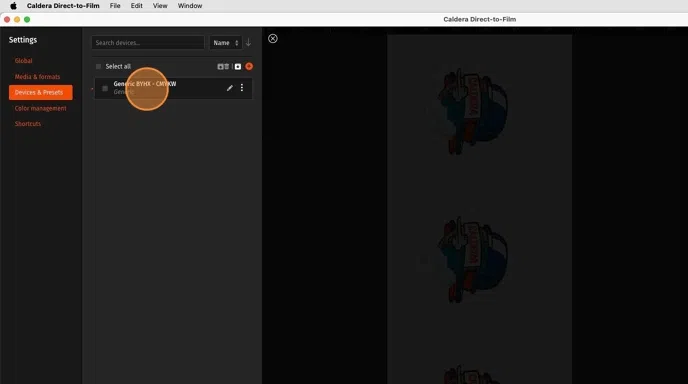

- Go to Devices & Presets:

- Select your printer and preset:

- Enable Custom droplet management:

Info

The manager is available for printers configured with 2 or 4 bits per plane.

Good to know

Bit depth refers to the number of bits used to represent the color or intensity of each pixel in an image. "Per plane" indicates the bits allocated for each color channel, determining the color depth of the output print file; a higher bit depth results in richer colors.

- Click on Edit, and the manager will open:

Use the Custom droplet manager

Either globally (default), or by overriding the values per ink, the options are:

Drop

The first values represent different drops that can be used in the output print file:

- If your printer is configured with 2 bits per plane, the manager allows you to customize three drops (1, 2, and 3).

- If your printer is configured with 4 bits per plane, the manager enables customization of a broader range of drops (1 to 15), providing more precise control over ink deposition, which can improve print quality and detail.

Depending on the printer, you can enable or disable droplets.

Maximum density (%)

Maximum density refers to the maximum amount of ink that can be applied to a substrate, expressed as a percentage. It indicates how saturated the print can be with ink. Higher maximum density can lead to richer colors and deeper blacks, but it must be balanced to avoid issues like ink bleeding or drying problems.

Relation to drops:

- The maximum density is influenced by the drops available. For example, if a printer can use a range of droplet sizes (as indicated by the bit depth), it can achieve different levels of ink saturation.

- In a preset with 2 bits per plane (3 drops), the maximum density might be lower than in a preset with 4 bits per plane (15 drops) because the latter can deposit more ink in finer increments, allowing for higher saturation without oversaturation.

- The maximum density for the latest drop is fixed at 100% in the software to maintain print quality and prevent oversaturation issues. However, you can adjust the densities of other droplets for more precise control.

Size (pL)

The size refers to the proportion of different droplets used in the printing process, and can affect the maximum density achieved in a print.

A well-optimized droplet size can help reach the maximum density without oversaturating the substrate, ensuring that the print maintains clarity and detail.