Why Re-Linearize?

- Accurate & consistent color reproduction

- Account for changing conditions

- Ink: Age of ink or batch

- Media: Age of media, lot number, change in white point, etc

- Printer Performance: Printhead health, maintenance, etc

- Environment: Heat, humidity, power, etc

- Monitor and account for changes in conditions (Process Control)

Relinearization process

Here's the process explained:

- Choose the Printer, Media and Mode then go to the Linearization tab and select Relinearize.

- Print and Read the (re)linearization patches, same as when creating a new profile.

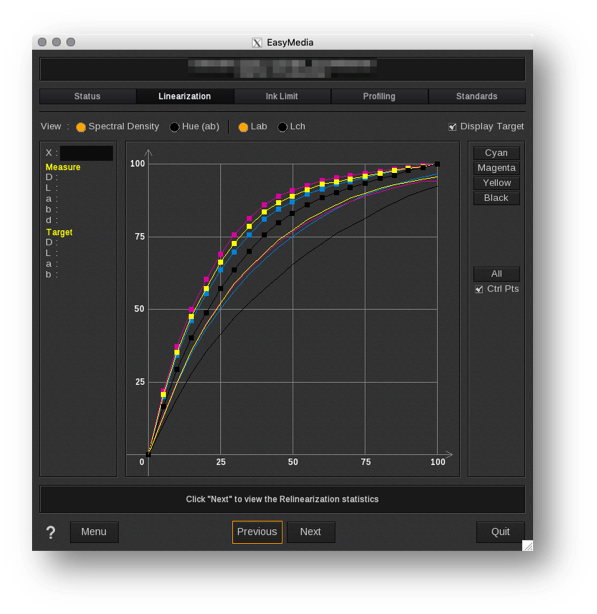

- Once the measurement is done, you will be able to compare the relinearization curves against the target curves.

Relinearization decisions

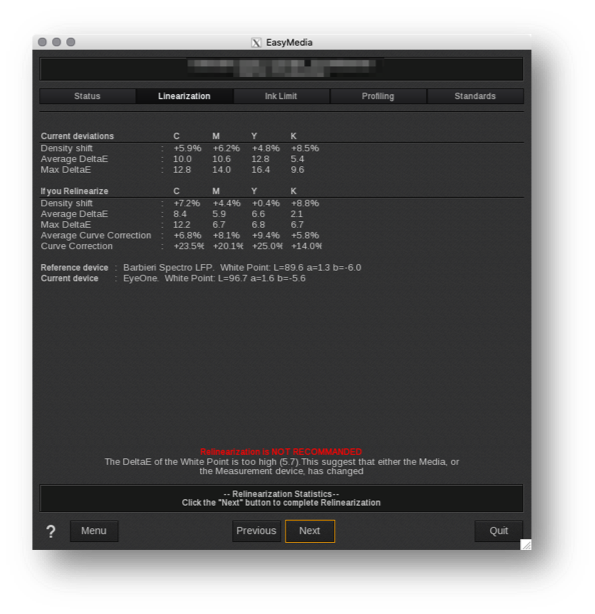

Reading deviations will be displayed based on current readings against the target data and EasyMedia will advise if the readings should be used or disregarded.

Info

Note that the "Curve Correction" information refers to the max curve correction.

In this example, relinearization is not recommended because the white point of the media has shifted significantly.

Also, note this may be due to a change in the reference device compared to the device used to re-linearize.

Additionally, the density of the re-linearization targets has deviated significantly (upward) indicating the condition or performance of the printer or environment has changed.

Ideally, under normal and stable conditions while using the same reference spectrophotometer the re-linearization process will pass.