What is Fogra?

The Fogra Research Institute for Media Technologies is a non-profit organization from Germany and an honorary member of the International Color Consortium (ICC). Their goal is to conduct scientific research at the service of the printing and media industry,

According to its own website, the "standardized FograCert testing program for materials, products and production processes guarantees safety whilst processing the materials, high-quality products and reliable manufacturing processes". In other words, a Fogra certificate validates that the production and the staff are delivering the best possible results.

This certification program is divided into:

- Prepress technology,

- Offset printing,

- Materials and environment,

- Digital printing.

It is from this last category, that the Process Standard Digital (PSD) emerges.

What is the PSD?

Fogra's Process Standard Digital (PSD) is an industry-oriented and standardized procedure for creating digital print products. This includes instructions, target values, recommendations, and minimum quality tolerances for "printing the expected".

Why is it important to obtain Fogra's PSD certification?

With the PSD certificate, service providers can show their quality approach and comprehensive understanding of output processes. Successful implementation of PSD offers printers the benefits of improved performance in cost, quality and time, with improved durability and reduced waste.

How to obtain Fogra's PSD certification?

- The first step to obtaining a certification is to verify that a printer with a certain configuration respects the PSD standard.

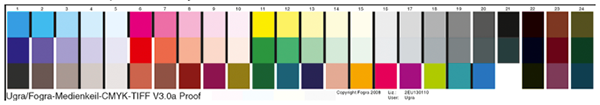

- This is when the MediaWedge 3.0 verification chart should be printed.

- Then, the ∆E color differences are calculated to check if the configuration respects the ∆E tolerances provided by the standard.

| Info - These ∆E PSD tolerances have been published since 2011 and in some years they present changes, so it is important to periodically check the Fogra website or Caldera's information. | ||||

What are the optimal conditions for validating the standard?

This article presents the optimal parameters to validate the Fogra PSD 2022 standard, based on a series of tests studying 23 parameters which were analyzed by performing and comparing 82 ICC profiles.

Context

Printers used

- Canon GP 2000 (Aqua-based inks)

- Epson SureColor S80600 (Eco solvent inks)

- Epson SureColor F7000 (Sublimation inks)

- Mimaki UCJV2300-8C (UV inks)

Media used

- Glossy vinyl (200 g/m2)

- Matte paper (192 g/m2)

- Glossy paper (170 g/m2)

- Standard glossy paper (235 g/m2)

- Standard proofing paper (240 g/m2)

- Transjet classic (75 g/m2) → for textile printing

- Transjet classic (100 g/m2) → for textile printing

Spectrophotometers used

- I1 Pro 3 Plus X-Rite

- I1 Pro 2 X-Rite

- I1 IO2 X-Rite

- Swing by Barbieri

- TotalColor by Barbieri

- TotalColor qb by Barbieri

Optimal conditions

Print speed

In fast mode, the ink limit is much lower which results in poor reproduction of dark colors.

In slow speed, the visual rendering is a little better than in normal speed, but the color is identical to that of normal mode.

It is therefore advisable to use the normal mode.

Media

A coated, glossy paper with a not too heavyweight is recommended.

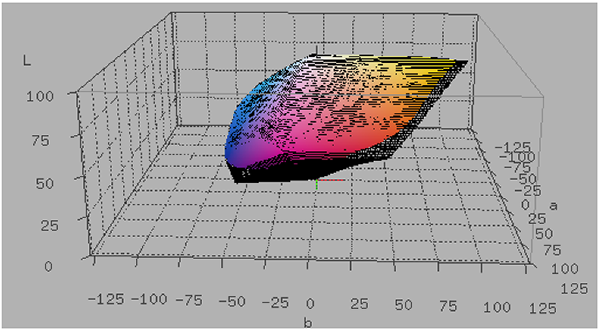

Vinyl provides results similar to glossy paper. Textiles have a lower color gamut.

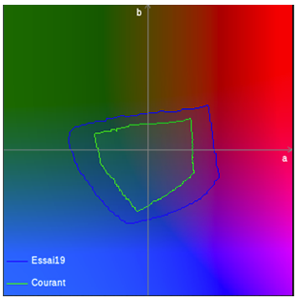

Matt paper (green) and semi-gloss paper (blue)

Other ink colors

Adding other ink colors increases the gamut. It is therefore recommended to use them to validate the standard if they are present on the printer.

Grey Component Replacement (GCR)

The GCR reduces the quality of the print, it gives a “grainy” rendering, however, it has no influence on the color. Any GCR can therefore be used for certification.

Ink limit

The ink limit has a big influence on the reproduction of dark colors. It is therefore advisable to use media that allows ink limits greater than 150.

Number of patches measured during profiling

For the ICC profile obtained to be reliable, it is advisable to measure more than 700 patches (320 patches are not sufficient).

Unidirectional/Bidirectional printing

For printers using eco-solvent-based inks, only unidirectional printing is recommended because the bidirectional mode halves the ink limit and therefore prevents the reproduction of dark colors, thus limiting the passage of the PSD 2022 standard.

For printers using aqua-based, UV, or sublimation inks, unidirectional and bidirectional modes achieve the same results. Thus, a bidirectional mode may be recommended to increase print speed without reducing print quality.

Comparison of bidirectional (colored) and unidirectional (black) gamuts

Head movement

On some printers, the head may move the width of the printer or only the width of the media.

A test on an eco-solvent-based printer, for example, showed that moving across the width of the media is not very useful because the ink limit is halved. It is therefore advisable to use a movement of the head across the width of the printer.

Spectrophotometer

- The spectrometer used must be certified to ensure that it is well calibrated and therefore that these measurements are reliable.

- Measurement condition M1 must be used.

- Non-contact measurements are not recommended if room light is not standardized.

- A 2mm opening can be used for papers and vinyls. However, for textile supports, only an 8 mm opening should be used.